In a major development for the electronics industry, researchers at Johns Hopkins University have unveiled new materials and a groundbreaking process aimed at advancing the production of microchips. These microchips are essential components found in various modern devices, including cellphones, cars, appliances, and airplanes. The team's innovative approach promises to create smaller, faster, and more affordable microchips, ultimately transforming the technology landscape.

The research team has discovered a manufacturing process that is both precise and economical, enabling the creation of circuits that are so tiny they are invisible to the naked eye. The findings, published in the esteemed journal Nature Chemical Engineering, highlight a significant leap forward in microchip technology. According to Michael Tsapatsis, a Bloomberg Distinguished Professor of chemical and biomolecular engineering at Johns Hopkins, companies have strategic roadmaps outlining their goals for the next 10 to 20 years. A critical challenge has been to find a method for producing smaller features on a production line with rapid and highly precise irradiation of materials, which is necessary to keep the process economically viable.

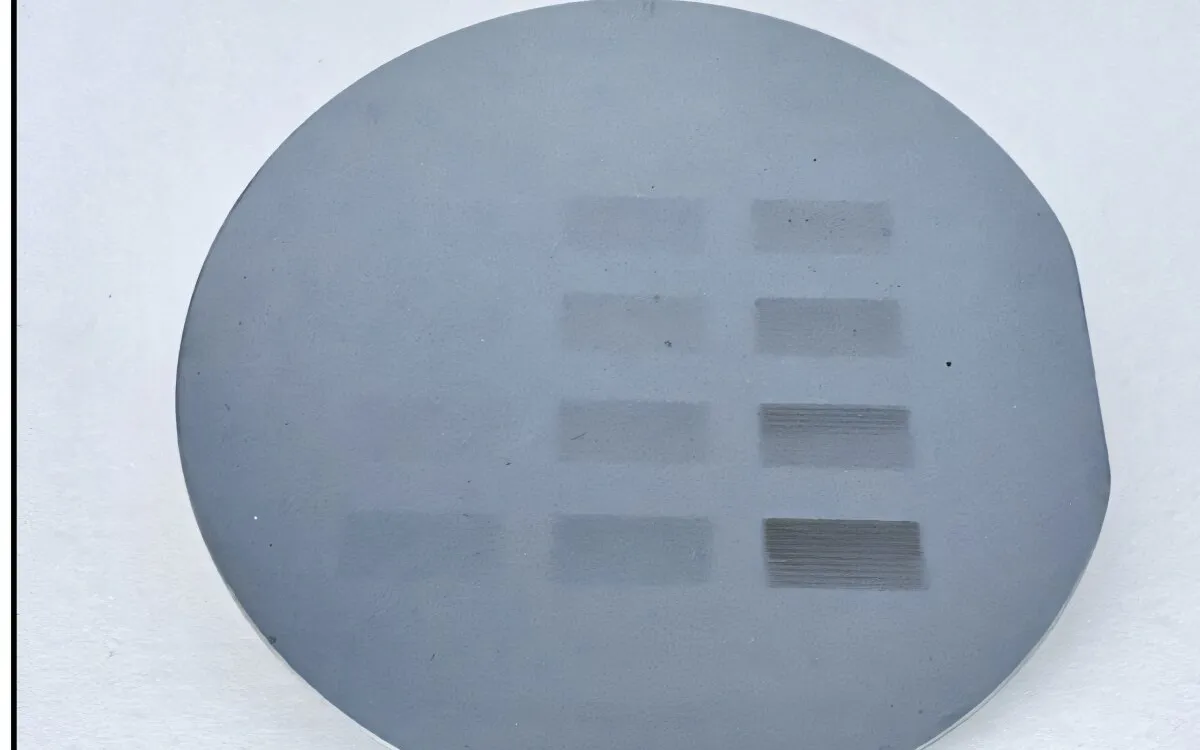

While advanced lasers capable of imprinting on these minuscule formats already exist, researchers needed to explore new materials and processes to support the creation of ever smaller microchips. Microchips are essentially flat pieces of silicon embedded with intricate circuitry that performs fundamental functions. During the manufacturing process, silicon wafers are coated with a radiation-sensitive material, known as a resist. When a radiation beam interacts with this resist, it triggers a chemical reaction that etches detailed patterns and circuitry onto the wafer.

However, traditional resists have proven inadequate for the higher-powered radiation beams required to etch finer details into microchips. The researchers from Tsapatsis's lab, in collaboration with the Fairbrother Research Group at Johns Hopkins, previously discovered that a new class of metal-organic resists could effectively accommodate the high-energy radiation process known as beyond extreme ultraviolet radiation (B-EUV). This advanced technique holds the potential to fabricate details smaller than the current benchmark size of 10 nanometers.

Utilizing metals like zinc, which absorb B-EUV light, the researchers can generate electrons that facilitate the essential chemical transformations needed to imprint circuit patterns onto an organic material called imidazole. This research is notable for being one of the first instances where scientists have successfully deposited imidazole-based metal-organic resists from solution at a silicon-wafer scale, allowing for nanometer precision in thickness control.

To develop the necessary chemistry for coating silicon wafers with metal-organic materials, the team integrated experiments and models from multiple prestigious institutions, including East China University of Science and Technology, École Polytechnique Fédérale de Lausanne, Soochow University, Brookhaven National Laboratory, and Lawrence Berkeley National Laboratory. The innovative methodology they devised, termed chemical liquid deposition (CLD), can be meticulously engineered, enabling researchers to rapidly experiment with various combinations of metals and imidazoles.

By manipulating the two components—metal and imidazole—scientists can enhance the efficiency of light absorption and optimize the subsequent chemical reactions. Tsapatsis explains that this flexibility opens the door to creating new and effective metal-organic pairings. The exciting aspect of this research is the identification of at least 10 different metals suitable for this chemistry, coupled with hundreds of organic options. The team has begun testing various combinations to formulate pairings specifically designed for B-EUV radiation, which they anticipate will be increasingly utilized in manufacturing over the next decade.

In summary, the groundbreaking work by Johns Hopkins researchers not only paves the way for smaller and more efficient microchips but also signifies a pivotal moment in semiconductor technology. With ongoing advancements in materials and manufacturing processes, the future of electronics looks promising.