On the morning of Christmas Eve 2016, residents of a house in Fraser, Michigan were startled by a series of peculiar popping sounds emanating from their walls. Initially attributing the noises to melting snow falling from the roof, they soon discovered the unsettling truth: the sounds were caused by bricks being pushed out of place as their home gradually succumbed to a sinkhole. This alarming event prompted an immediate evacuation of the house and several nearby properties while authorities conducted an assessment to determine the cause of the incident.

Authorities found that the sinkhole was triggered by a collapsed sewer interceptor, which posed a serious threat to several homes and a long stretch of Fraser’s busy 15 Mile Road. Vince Astorino, the Operations Director at the Macomb County Public Works Office, highlighted the impact of this incident on the community. "This was quite the impact to our system and community," he noted. Astorino, who oversees the operations of the county's wastewater infrastructure, explained that a failure in an 11-foot diameter sewer pipe, approximately 70 feet deep, drastically reduced wastewater flow in a section critical to the system relied upon by around 800,000 residents.

Thanks to the swift action of Astorino and his team, bypass systems were implemented quickly to prevent sewage backup into homes, and ultimately, only one building—the one where the popping noise was first heard—required demolition. However, it took nine months to fully replace the damaged section of pipe, which extended roughly 4,000 feet, costing taxpayers around $75 million. This figure does not account for the additional financial impact on residents and local businesses due to the disruption caused by the sinkhole.

To prevent similar disasters, regular inspection of sewer lines is essential. Identifying cracks and fissures that can lead to soil ingress and eventual pipe collapse is crucial. However, inspecting large sewer networks can be challenging due to the dark, cramped, and hazardous conditions inside sewer pipes. Traditional inspection methods, which usually involve a tethered, remotely operated crawler or in-person inspections, can be slow and costly.

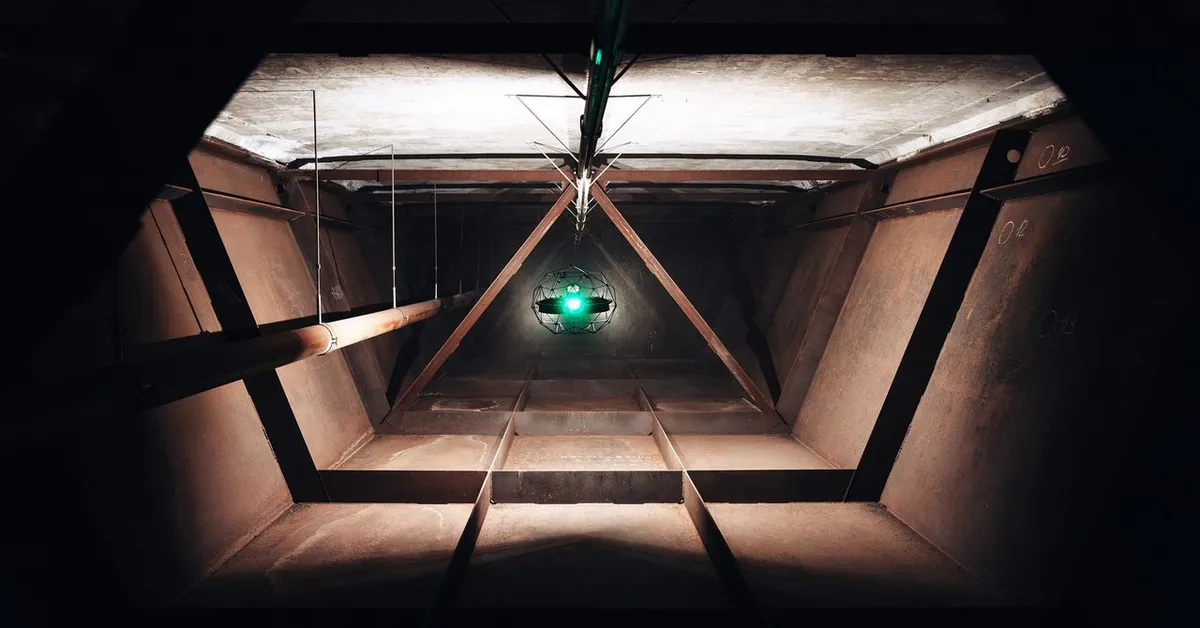

Enter drones—specifically designed to navigate confined spaces, a new generation of flying robots is now being deployed for sewer inspections. One notable example is the Elios 3, created by the Swiss company Flyability, which is already being utilized by major industry players like Veolia. This drone is equipped with a protective cage, impact-resistant exoskeleton, a 16,000-lumen lighting rig, a 4K camera, and LiDAR capabilities, allowing it to explore dark and dusty pipes while generating live 3D models of the environment.

Eloise McMinn Mitchell, the Communication Manager at Flyability, reported significant growth in sales due to the Elios 3's efficiency compared to traditional human inspections, especially for sewer assessments. “To inspect a stretch of sewer underneath a road, you’ll need teams of at least four people and have to divert traffic in multiple locations. With the drone, you just need two people, eliminating confined space risks,” she explained. The cost savings are substantial, with an average reduction of 40 percent compared to traditional methods, allowing inspectors to cover up to 900 meters in a day with the drone versus just 400 meters manually.

In May 2024, Macomb County took a significant step forward by adopting a technology-led approach that combines the Asio X drone from Flybotix with a software program called SewerAI. The total investment for this innovative technology was approximately $100,000, a substantial savings compared to the previous $1 million spent on manual inspections every three years. The Asio X drone is designed to capture high-quality video and data from sewer systems while navigating various pipe sizes, enhancing the inspection process.

Astorino noted the dramatic improvements in efficiency with the new system, stating, “It’s a night and day difference.” While the Asio X requires manual control, its operational efficiency allows for significant data collection during inspections. The drone's antenna is lowered into a manhole to establish communication with the operator, who then navigates from one manhole to the next, capturing video, LiDAR scans, and gas readings throughout the process.

The data collected by the drone is sent to contractors at SewerAI, where it is analyzed using advanced algorithms to identify defects automatically. Astorino emphasized the time-saving benefits of this technology, with analysis turnaround times reduced to 10 days—often completed within 24 hours. This rapid analysis allows for timely repairs, preventing the deterioration that leads to costly incidents like the 2016 sinkhole.

Macomb County has become a trailblazer in the utilization of drones and AI for underground infrastructure inspection, earning two in-state awards for their innovative approach. Astorino remains committed to exploring further advancements, stating, “It’s hard to count out great leaps forward in technology around this space, especially with the great AI race taking place all around us. We’re keeping our options open.” This ongoing commitment to modernization underscores the importance of leveraging technology to enhance infrastructure safety and efficiency.